Search Example: “SUS” “Fe” “t 0.1” “φ” “HSW-03”

| image | Material A | t/D | Material B | t/D | Spot welder | Electrode | Welding situation |

|---|---|---|---|---|---|---|---|

| SUS | t 0.7 | SUS | t 0.7 | HSW-01 HSW-PC1 | PSW-T1 HSW-EB1 | Welded two locations with different voltage settings |

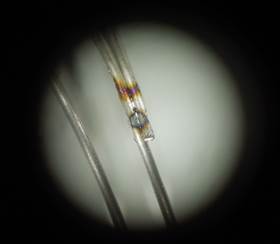

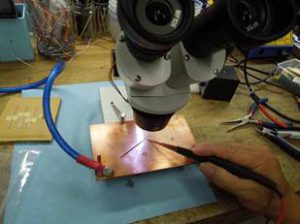

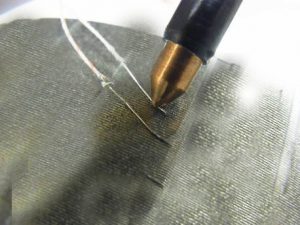

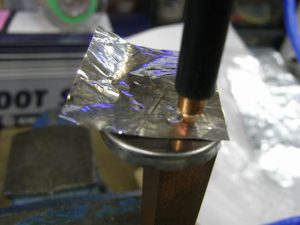

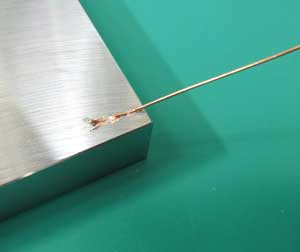

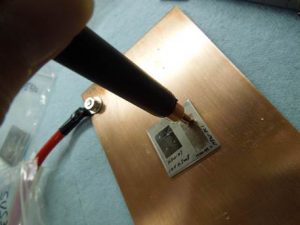

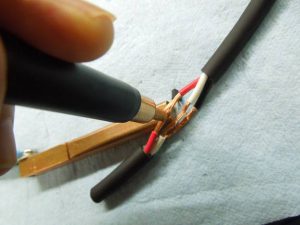

| Cu | φ 0.3 | Cu | φ 0.3 | HSW-03 | HSW-EB1 | Welded at 6.5V 1.6mS. When the pulse width was increased from 1.6mS to 1.8mS, the copper wire was melted and buried in the resistance solder. I used it by cutting it so that it can grip 1 mm of the resistance end, but it is recommended to make a dedicated electrode that can firmly grip the resistance electrode part. |

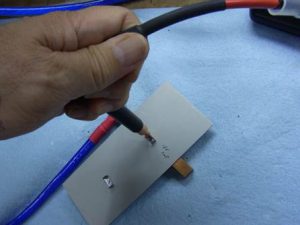

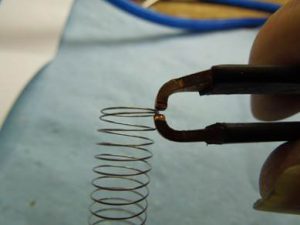

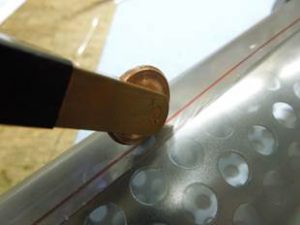

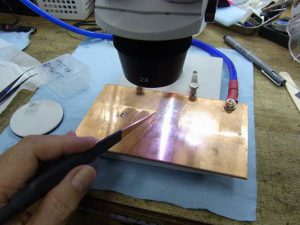

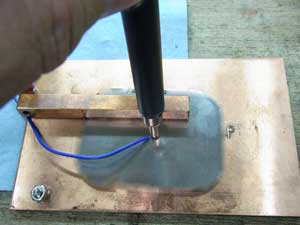

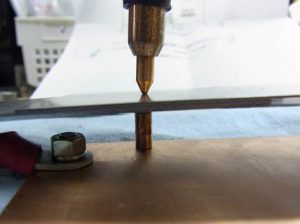

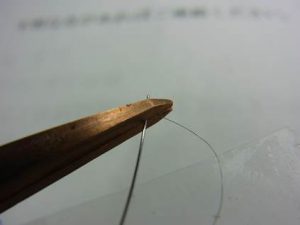

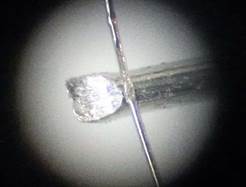

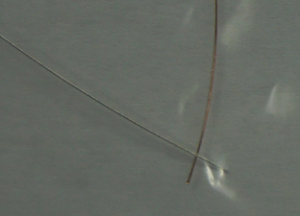

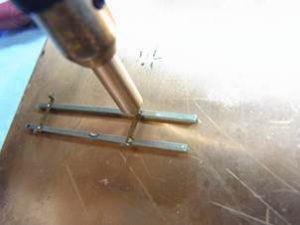

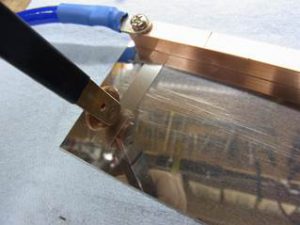

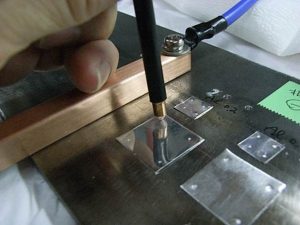

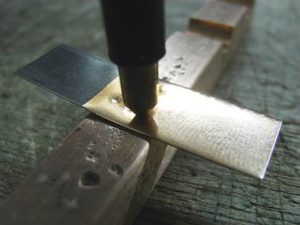

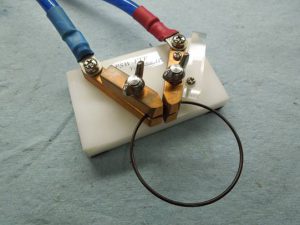

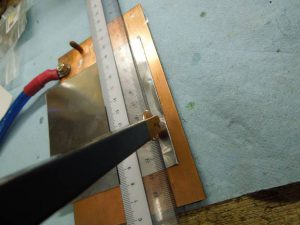

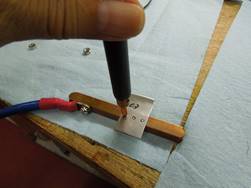

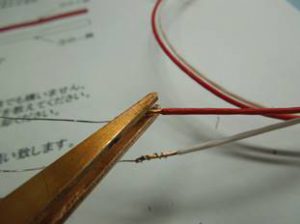

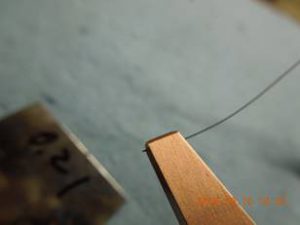

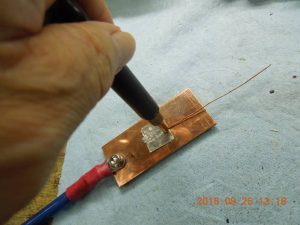

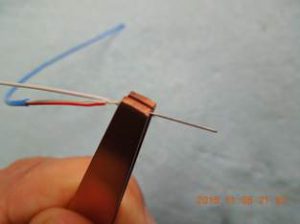

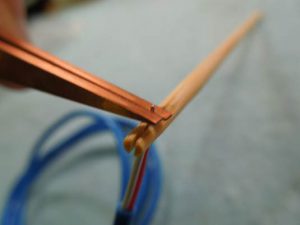

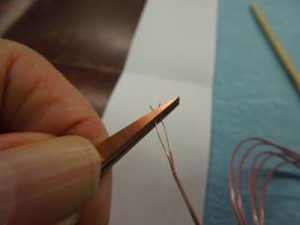

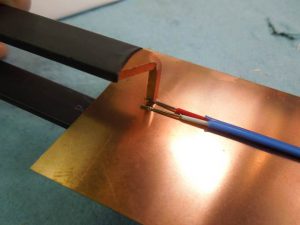

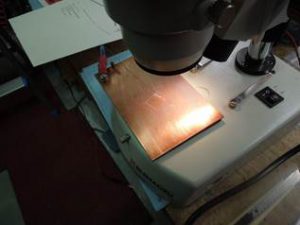

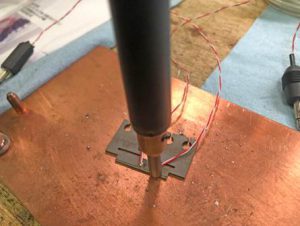

| SUS | t 0.1 | Fe | t 0.8 | HSW-03 | PSW-P2 HSW-EB1 | Welded by the method shown in the photo |

| SUS | φ 2.0 | SUS | φ 2.0 | HSW-03 | HSW-EB1 | Maximum setting for both voltage and pulse width The obtained strength is low and it is about temporary fixing, and half of them peeled off when dropped freely from a height of about 30 cm. |

| K tc | φ 2.0 | T tc | φ 2.0 | HSW-02 | PSW-T1 | Welded with HSW-03 machine, which can read numerical values, and then welded with HSW-02A machine and HSW-TC1 electrode for condition setting and shooting. |

| Al | t 0.15 | Al | t 0.1 | HSW-03 | PSW-P2 HSW-FB2 | 25V 0.3ms |

| Cu | t 0.01 | Ni | t 0.1 | HSW-03 | PSW-P2 HSW-FB2 | 25V 0.6ms Since there is a hole at 1.2mS, it seems that about 0.6mS is good. |

| Al | t 0.4 | Ni | T 0.1 | HSW-03 | PSW-P2 HSW-EB1 | Welding was possible without any problems. If you forcibly peel it off, the material will break. |

| Al | t 0.15 | Ni | t 0.1 | HSW-03 | PSW-P2 HSW-EB1 | It was necessary to consider the heat dissipation on the aluminum side when selecting the electrodes, and the heat dissipation was insufficient. |

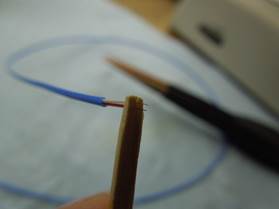

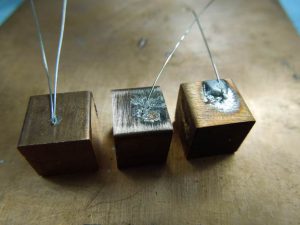

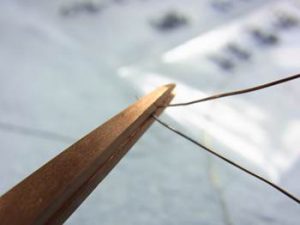

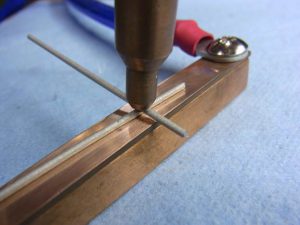

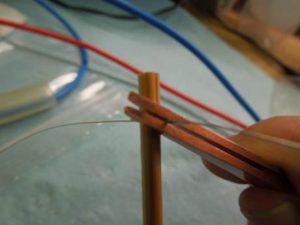

| K tc | φ 1.0 | K tc | φ 1.0 | HSW-03 | HSW-TC1 | In order to keep the strands parallel, we welded with a split in the bamboo skewer and welded without any problem. |

| Cu | Block | K tc | φ 3.0 | HSW-03 | HSW-TC1 HSW-FB2 PSW-P2 | It was not possible to weld the thermocouple directly to the copper block |

| Cu | t 5.0 | T tc R tc | φ 0.3 | HSW-03 | HSW-FB2 PSW-P2 HSW-T1 | Cut the tip of each wire of the thermocouple and weld it to the end of the copper alloy work at 0.3 to 0.5 ms. |

| Ti | t 0.1 | Ti | t 0.1 | HSW-01 | HSW-W02 | Welded easily. If you need less strength than this, you need to add HSW-PC1 (power controller). If you need more strength or spot diameter, you need HSW-02A or HSW-03. |

| Fe:Sn | t 0.5 | Ni-Cr | φ 0.3 | HSW-01 | HSW-EB1 HSW-P1N | Welded. Welding strength can be adjusted by adjusting the voltage. |

| K tc | t 0.5 | K tc | φ 0.3 | HSW-01 | HSW-PC1 | Welded |

| Al:Li-po | t 0.2 | Ni | t 0.15 | HSW-03 | HSW-W2 | Welding results are good. Strength can be increased by increasing the number of welding points or changing the shape of the aluminum side electrode. Nickel material is 0.08t and 0.15t |

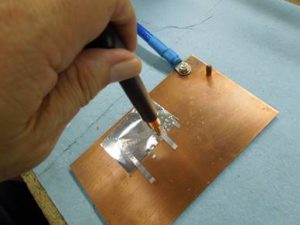

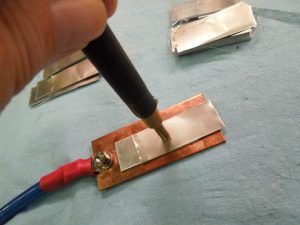

| Fe | t 50.0 | Fe | t 0.01 | HSW-03 | HSW-CL1 PSW-P2 | If it is 0.3t or less, it can be welded with HSW-02A + HSW-PC1 + HSW-F1N. For 0.5t, the one with strong spot marks used the PSW-P2 electrode shown in the photo. |

| Al | t 1.0 | T tc | φ 0.1 | HSW-03 | HSW-TC1 HSW-FB1 | To see how the thermocouple wires are welded, I welded each wire to the Al plate separately. Also, after creating the thermocouple contact, it is also welded to the Al plate. |

| SUS | t 0.5 | SUS | t 0.5 | HSW-03 | HSW-W2 PSW-02 | Any model can be welded. HSW-03 machine has more room for setting |

| K tc | φ 0.65 | K tc | φ 0.65 | HSW-02 | HSW-W2 | Weldable It is possible to increase or decrease the strength |

| SUS | t 2.0 | SUS | φ 1.5 | HSW-03 | PSW-P2 HSW-CL1 | Welding is possible with a voltage of 25 V and a pulse width of 0.77 mS to 2.5 mS. Since the welding mark was large, it is necessary to match the shape of the electrode tip to the work and process it. |

| SUS | φ 0.35 | SUS | φ 0.35 | HSW-03 | HSW-W2 | Weldable Can also be used with HSW-02A spot welder + HSW-PC1 |

| solar cell | solar cell | K tc | φ 1.0 | HSW-03 | NG | Not weldable Difficult to raise the temperature without breaking the Ag side used for the pattern |

|

| K tc | φ 0.1 | K tc | φ 0.1 | HSW-03 | HSW-TC1 | Can be welded using HSW-03 and thermocouple electrodes There is a sufficient range of adjustment for both voltage and energization time. |

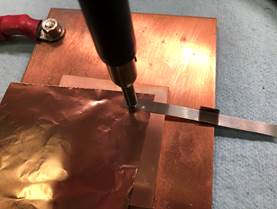

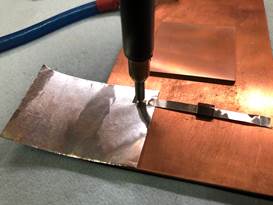

| Ti | t 4.0 | Cu | t 0.1 | HSW-03 | PSW-P1 HSW-FB2 | Welding is difficult for both Cu and Ag, so pressure is weakened and flash welding is required. If the pressure is too weak, the copper foil will be punctured. |

| T tc | φ 0.3 | Cu | t 1.0 | HSW-03 | NG | Cannot be welded with HSW-03, HSW-02A spot welders |

| T tc | φ 0.3 | T tc | φ 0.3 | HSW-03 | HSW-TC1 | Polarity setting: + side: Cu side -Side: Constantin side Voltage 20V, welding pulse width 0.7mS |

| Pt | t 0.8 | Pt | φ 0.5 | HSW-02 | PSW-P1 HSW-FB2 | Since Pt wire tends to weld to the electrode during welding, it is better to reduce the voltage a little. |

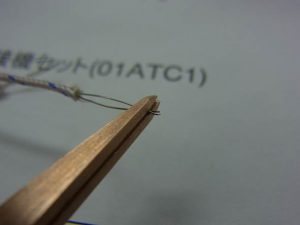

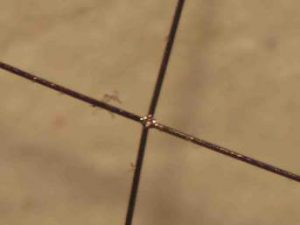

| K tc | φ 0.025 | K tc | φ 0.025 | HSW-03 | HSW-T1 HSW-FB2 | Fixed with tape on a flat plate electrode with the strands crossed Hold down with T1 electrode from above and spot weld at 3.6V 0.02mS |

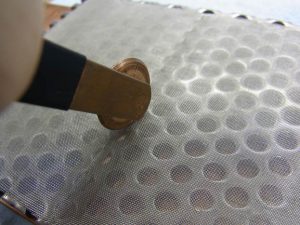

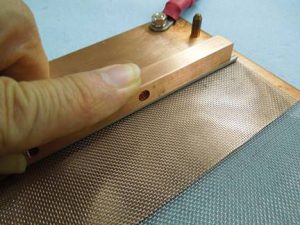

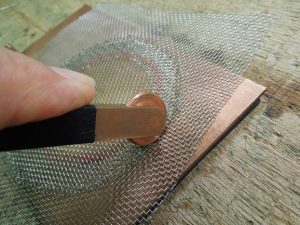

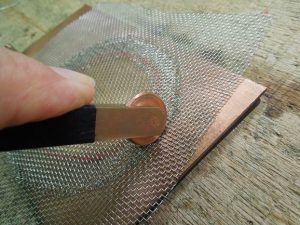

| SUS | 100# 60 | SUS | micro-screen | HSW-03 | PSW-R2 HSW-EB1 | Welded in seam mode. The rod-shaped electrode is applied to the back surface of the work. By shaping the contact surface, it is possible to reduce welding marks and slightly adjust the welding width. |

| SUS316 | t 10.0 | SUS | φ 0.25 | HSW-03 | HSW-T1 HSW-FB2 | Weldable The T1 electrode connects the two reeds together to the negative side of the welder. The FB2 electrode is welded with the + side cable connected and the wire inserted in the hole. Be careful not to let the electrodes come into contact with the protective surface Welding strength can be adjusted by setting the energizing time |

| Fe | t 10.0 | Ag | φ 0.5 | HSW-03 | Custom HSW-FB2 | Seam welding: 10V, 0.2-0.5mS Uses a custom electrode that uses two HSW-EB1 |

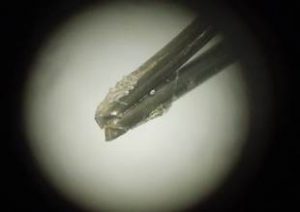

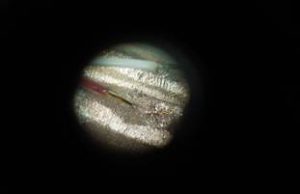

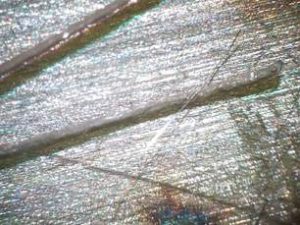

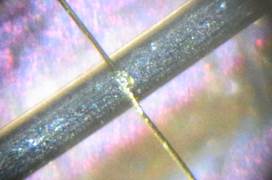

| Cu | φ 0.15 | Ni-Cr | φ 0.02 | HSW-03 | HSW-T1 HSW-FB2 | Weldable The surface of the Cu wire is very uneven, so it is necessary to select a location when applying precision welded electrodes. |

| C5210 | t 0.6 | SKD11 | φ 1.0 | HSW-03 | PSW-P1 HSW-FB1 | Dedicated electrodes are required due to unstable electrode contact Since the current is concentrated on the flange part, it is better to use stud welding. |

| Ni/Cu | t 0.2 | Ni/Cu | t 0.2 | HSW-03 | NG | Unweldable Welding was not possible due to low heat generation due to low resistance. |

|

| Al | t 0.4 | Al | t 0.4 | HSW-03 | NG | Unweldable Welding was not possible due to low heat generation due to low resistance. |

|

| T tc E tc T tc | φ 0.3 φ 0.2 φ 0.1 | T tc E tc T tc | φ 0.3 φ 0.2 φ 0.1 | HSW-01 | HSW-T1 HSW-FB2 | T thermocouple φ0.1: 14V E thermocouple φ0.2: 9V T thermocouple φ0.1: 7V |

| Ni | t 0.1 | SUS/Ni | φ 0.2×30 | HSW-03 | HSW-TC1 | Weld 10 times at 21V: 1mS and weld Ni terminals twice at 21V: 3.8mS Welded with 24.8V2.5mS silver tungsten electrode If necessary, it is possible to apply additional current for welding. |

| Mo | t 1.0 | E tc | φ 0.2 | HSW-03 | HSW-T1 HSW-FB2 | Welding is also possible with HSW-02A + HSW-PC1, Welding with HSW-03 where numerical values can be seen Welding strength can be adjusted. |

| Al | t 20.0 | Al | ? | HSW-03 | PSW-P2 HSW-FB2 | Weldable Welding strength can be increased or decreased |

| T tc | φ 0.2 | Cu | t 0.05 | HSW-03 | PSW-P2 HSW-FB2 | Weldable Welded at 9.5V, 0.33mS and then welded to copper foil by 25V, 30ms seam welding. |

| Fe | φ 3.0 | Fe | φ 2.0 | HSW-03 | PSW-TFT | HSW-03 is not strong enough, so it can be welded with HSW-04 machine. |

| Ni/Cu | φ 0.1 | Ni/Cu | φ 0.1 | HSW-03 | HSW-TC1 | Welding around 9V: 80μS Chromel side is-side, Constantan is + side |

|

| SUS | φ 4.0 | SUS | φ 4.0 | HSW-03 | PSW-P1 HSW-EB1 | Weldable Welding strength may be insufficient for workpieces of 3 to 4φ. |

| SUS | mesh | SUS | mesh | HSW-03 | HSW-EB1 | Seam welding mode 10V 0.1mS to 24V 1ms welding Welding while applying force to the left and right meshes with rod-shaped electrodes |

| SS400 | t 10.0 | SUS304 | t 0.3 | HSW-01 | HSW-P1S HSW-CL1 | Can be welded with HSW-01A machine PSW-P2 recommended |

| Fe:Zn | φ 3.0 | Fe | φ 0.5 | HSW-03 | PSW-P1 HSW-FB2 | Weldable It is necessary to increase the electrode pressurization pressure |

| Fe:Zn | φ 2.0 | Fe:Zn | φ 2.0 | HSW-03 | HSW-W2 | Weldable |

| Fe:Sn | t 0.3 | Fe:Sn | t 0.3 | HSW-03 | PSW-P1 HSW-EB2 | Can be welded at 25V, 30mS |

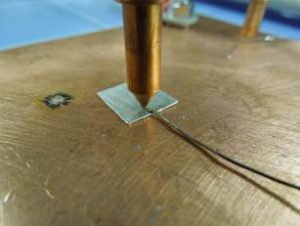

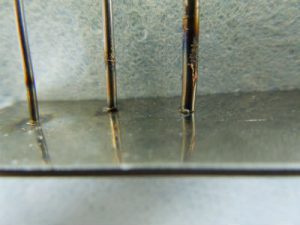

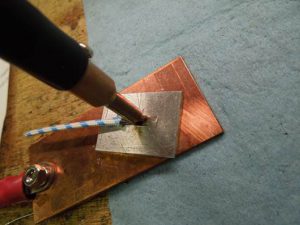

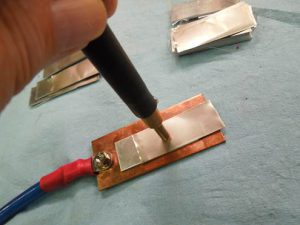

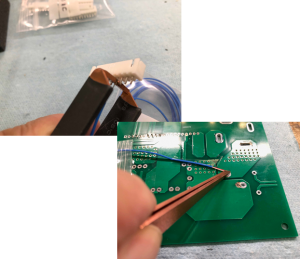

| SK-4 | t 2.0 | K tc | φ 0.32 | HSW-02 | PSW-P1 HSW-EB2 | Welding is possible at around 8V 0.4 to 1mS by the method shown in the photo. |

| SUS | φ 3.0 pipe | SUS | φ 3.0 pipe | HSW-03 | custom | Welding is possible from 24V 0.75mS to 2mS |

| KOVAR | ? | Ag | ? | HSW-03 | PSW-P1 HSW-EB2 | 17V pulse width 200μS can be welded (1) Welding is possible by applying electrodes from above and below. (2) Welding is possible with electrodes from the top and rod-shaped electrodes below. (3) Unstable when a rod-shaped electrode is used for the Ag piece |

| SUS430 | t 4.0 | SUS430 | t 2.0 | HSW-03 | PSW-P1 HSW-CL1 | Weldable at 25V, 30mS |

| Al | t 0.02*20 | Al | t 0.02*20 | HSW-03 | PSW-R2 HSW-FB2 | 23V, 330μS can be welded in seam welding mode |

| Fe | ? | SUS | ? | HSW-02 | PSW-P1 Custom | Weldable |

| Parts | ? | Parts | ? | HSW-03 | PSW-TC1 | Weldable Setting 9V 1.3ms |

| Parts | ? | Parts | ? | HSW-03 | PSW-TC1 | Weldable |

| Al | t 10.0 | K tc | φ 0.1 | HSW-01 | HSW-P1N PSW-TC1 | Weldable The thermocouple side is the-side, and the aluminum plate side is the + side. |

| SUS316 | φ 0.08 | SUS mesh | t 0.14 | HSW-02 | PSW-R2 HSW-EB1 | Can be welded in seam welding mode |

| Cu | t 0.1 | Cu | t 0.15 | HSW-03 | PSW-P1 HSW-FB2 | Weldable Insufficient strength due to welding limit of HSW-03 machine |

| SUS | φ 0.25 | Ni/Fe | ? | HSW-03 | PSW-T1 HSW-FB2 | Weldable Setting 4.4V, 0.03mS Electrodes are made of chrome copper |

| SUS | t 0.4 | Cu:Sn | AWG20 | HSW-03 | PSW-P1 HSW-FB2 | Weldable: Setting 24V, 5mS The rod-shaped electrode is processed and applied to a wide range from the top. |

| Parts | t 5.0 | Fe | t 0.2 | HSW-03 | PSW-P1 HSW-FB2 | Insufficient welding strength due to painting Can be welded if peeled off |

| SPHC | t 1.6 | SUS430 | t 0.63 | HSW-03 | PSW-P1 HSW-FB2 | Setting 25V, 30mS Welded at maximum output, but insufficient welding strength |

| Pt | φ 0.05 | Pt | φ 0.25 | HSW-03 | PSW-TC1 | Setting 7V, 0.05mS Weldable |

| Ni Parts | t 1.0 | SS400 | t 3.0 | HSW-03 | PSW-P1 HSW-FB2 | Insufficient strength at maximum value Welding is possible with HSW-04 |

| Cu | φ 0.1 | SUS | φ 0.05 | HSW-01 | PSW-T1 HSW-FB2 | Weldable |

| Cu/Sn | t 0.08 | Ag | φ 0.5 | HSW-02 | HSW-P1N HSW-FB2 | Weldable Welding pulse width can be increased or decreased |

| Cu:Ni | t 0.2 | Cu | t 0.02 | HSW-03 | NG | Not weldable | |

| Al | t 0.2 | Al | t 0.03 | HSW-03 | PSW-P1 HSW-FB2 | Weldable Setting 25V, 7ms |

| W | t 1.0 | K tc | φ 0.2 | HSW-03 | PSW-P1 HSW-FB2 | Weldable The setting in seam welding mode is relatively good |

| Pt | φ 0.08 | Pt | φ 0.08 | HSW-03 | PSW-T1 HSW-FB2 | Weldable Setting 10.5V, 0.08mS |

| Ni | φ 0.2 | Cu | φ 0.2 | HSW-03 | PSW-T1 HSW-FB2 | Weldable Setting seam welding 14.5V, 0.5mS |

| Ti | φ 0.2 | Pt | φ 0.08 | HSW-03 | PSW-T1 HSW-FB2 | Weldable Setting seam welding 14.5V, 0.5mS |

| Cu | t 0.22 | Ni | φ 0.17 | HSW-03 | PSW-P1 | Weldable, Welding strength adjustable Setting 12.6V, 1mS |

| SUS | t 0.05 | SUS | t 0.05 | HSW-01 | HSW-W2 HSW-P1S | Weldable Setting 12V, 1.4mS |

| Al | t 0.03 | Al | t 0.1 | HSW-03 | PSW-P1 HSW-FB2 | Weldable |

| Cu | t 0.01 | Al | t 0.1 | HSW-03 | PSW-P1 HSW-FB2 | Weldable |

| Al | t 0.02 | Ni | t 0.1 | HSW-03 | PSW-P1 HSW-FB2 | Weldable |

| Cu | t 0.02 | Ni | t 0.1 | HSW-03 | PSW-P1 HSW-FB2 | Weldable |

| SUS | mesh 100 | SUS | mesh 100 | HSW-03 | PSW-R2 HSW-FB2 | Weldable, strength adjustment possible Setting 10V, 0.1ms |

| Fe | t 20.0 | Fe | t 0.01 t 1.5 | HSW-03 | PSW-P1 HSW-FB2 | Weldable |

| SUS304 | mesh | SUS304 | mesh | HSW-03 | PSW-R2 HSW-FB2 | Weldable |

| Cu/Ni/Zn | t 3.0 | PBP | t 0.2 | HSW-02 | PSW-P1 HSW-FB2 | Weldable |

| SUS | t 4.0 | SUS | mesh 100 | HSW-03 | PSW-R2 HSW-FB2 | Seam weldable Setting 17V 0.16ms |

| Cu | φ 1.0 | SUS | φ 1.0 | HSW-03 | HSW-F1N HSW-EB1 | Weldable Setting 6.4V 0.08ms Dedicated electrode is required when welding Cu wire and SUS wire in parallel |

| Fe | ? | K tc | φ 0.3 | HSW-03 | PSW-P1 HSW-EB1 | Setting 7V 26ms Welding is possible without problems for the purpose of welding thermocouple wires |

| Fe | t 50.0 | K tc | φ 0.3 | HSW-03 | PSW-P1 HSW-EB1 | Setting 14V 60ms Welding is possible without problems for the purpose of welding thermocouple wires |

| SUS tc | φ 1.5 | K tc | φ 0.1 | HSW-03 | NG | Not weldable |

| Cr/Ni | φ 0.2 | Cu/Ni | φ 0.1 | HSW-03 | PSW-TC1 | Weldable Setting 9V, 80μs Chromel side is-side, Constantan is + side |

|

| Fe | t 20.0 | Pt | φ 0.08 | HSW-01 | PSW-P1 HSW-FB2 | Weldable Can be set from 13 to 24V depending on the required strength |

| Ni/Mo/Cu | t 0.1 | Ni/Mo/Cu | t 0.1 | HSW-03 | HSW-F1N | Weldable Setting 18V, 0.2ms If welding strength is required, double welding or spot welding |

| Au-0.07Fe | φ 0.2 | Cr/Ni | φ 0.2 | HSW-03 | PSW-TC1 | Weldable Au-0.07Fe (φ0.2) + Chromel (φ0.2) setting 10V, 0.4mS Au-0.07Fe (φ0.2) to each setting 10V, 1.0mS |

| T tc | φ 0.32 | T tc | φ 0.32 | HSW-01 | PSW-PC1 HSW-EB1 | Weldable Polyester coating must be peeled off in advance |

| Cu | t 1.5 | Cu | φ 0.6 | HSW-03 | NG | Not weldable |

| Film | ? | Fe | t 10.0 | HSW-03 | PSW-P2 | Weldable Setting 13V, 1ms Surface coating needs to be peeled off at 230 ° C |

| SUS430 | t 0.5 | SUS304 | t0.3 | HSW-03 | PSW-P1 HSW-EB1 | Weldable Setting 10.7V, 0.5-2.0ms |

| Cu | ? | Ni | φ 0.1 | HSW-03 | PSW-TC1 | Weldable Setting 9V, 80μs It is necessary to remove the insulating film |

| K tc | φ 0.3 | K tc | φ 0.3 | HSW-03 | PSW-TC1 | Weldable Setting 7V, 0.2ms |

| SUS | mesh 100 | SUS | t 0.4 | HSW-01 | PSW-P1 HSW-FB2 | Weldable Both flat electrode and rod electrode can be welded |

| Fe | φ 1.5 | Ti:Pt | φ 1.5 | HSW-03 | PSW-P1 HSW-EB1 | Weldable Settings 16V, 0.4ms-20V, 10ms |

| Fe | φ 1.2 | Fe | φ 1.2 | HSW-03 | PSW-P1 HSW-EB1 | Weldable Setting 24V, 15ms |

| SMA | φ 0.3 | SMA | φ 0.3 | HSW-03 | PSW-TFT | Weldable Welded at 9V 300μS. The overlapping part is HSW-TC1 double pulse mode 9V 1.4mS |

|

| SUS | t 0.04 | SUS | t 0.04 | HSW-01 | PSW-P1 HSW-FB2 | Weldable |

| SUS316 | t 0.4 | SUS304t | t 2.0 | HSW-02 | PSW-P1 HSW-CL1 | Weldable Two-point welding because the strength was a little insufficient The clip side is the + side and the welding stick side is the-side. |

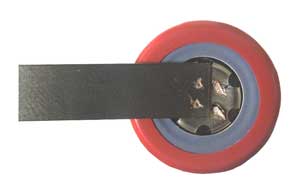

| Al | t 0.01 | CR2032 | Battery | HSW-01 | HSW-P1S HSW-EB1 | Weldable Setting 20V, 0.24ms Welding strength can be adjusted within the range where the aluminum foil does not melt |

| Fe | ? | Fe | ? | HSW-03 | HSW-W2 | Weldable Setting 20V, 10ms |

| Bi-Te | t 4.0 | Ni | t 0.1 | HSW-03 | PSW-P1 HSW-EB1 | Weldable Settings 6.6V, 0.3-0.9ms 11V, 0.4ms Welding was difficult because Bi-Te has low strength and is damaged just by energizing. Although it was temporarily welded to the Ni plate, it could be easily peeled off. If it exceeds 11V, 0.4mS, it will be gasified by the heat generated during welding. |

| SUS304 | t 0.6 | SUS304 | t 0.4 | HSW-03 | custom | Weldable (double pulse mode) Setting 0.4φ 14.7V 0.5mS // 0.5φ 10.3V 0.67mS // 0.5φ 22V 0.37S // 0.6φ 22V 0.37mS If the SUS material protruding from the electrode is not shortened, it will be thermally denatured as the temperature rises. Uses HSW-03 machine with double pulse function that can prevent splash generation during welding |

| Cu | t 5.0 | Fe | ? | HSW-03 | PSW-P1 HSW-EB1 | Weldable Settings 7V, 0.3ms / 14V, 1ms Adjustable as long as the work does not melt |

| Cr/Ni | φ 0.1 | Cu/Ni | φ 0.1 | HSW-03 | PSW-TC1 | Weldable The chromel side is the-side and the constantan is the + side. |

|

| K tc | φ 0.65 | Fe | t 3.0 | HSW-02 | HSW-P1N HSW-EB1 | Weldable Setting 15V, 1.5ms |

| K tc | φ 0.3 | Fe | t 2.0 | HSW-02 | HSW-P1N HSW-EB1 | Weldable Welding strength can be adjusted by adjustment. By using HSW-CL1, it is more stable and there are no welding marks on the steel plate. |

| K tc | φ 0.05 | Fe parts | t 1.0 | HSW-02 | PSW-TC1 HSW-FB2 | Weldable setting 5.4V, 80μS After welding the alumel wire and the chromel wire, Weld a thermocouple to a screw with a rod-shaped electrode I pressed the machine screw on the rod-shaped electrode using nickel 0.25 mm thick, Dedicated electrodes are recommended to improve the accuracy of welding points |

| SUS304 | t 11.0 | Ni | t 0.15 | HSW-01 | HSW-P1N | Weldable setting 20V HSW-03 is required when welding Ni t 0.15 |

| Ni/Cr | t 0.23 | Ni/Cr | t 0.23 | HSW-03 | custom | Weldable Setting 17-20V, 0.3ms, then seam welding Welding is required while abutting on a flat surface |

| SUS | t 0.4 | SUS | t 0.4 | HSW-03 | PSW-P1 HSW-EB1 | Weldable Setting 4V, 20ms |

| T tc | φ 0.3 | T tc | φ 0.3 | HSW-01 | PSW-TC1 | Weldable Setting 8V, 0.25ms |

| parts | ? | parts | ? | HSW-03 | PSW-TC1 | Weldable, setting 11V, 0.4ms seam welding Possible by overlapping and welding the ends It is necessary to remove the oxide film before welding |

| Fe(Steel blade) | t 0.45 | Fe | t 1.0 | HSW-03 | PSW-P1 HSW-EB1 | Weldable Welding at 8 second intervals at 24V, 10ms |

| SUS | t 1.0 | SUS | t 2.0 | HSW-03 | PSW-P1 HSW-EB1 | Weldable |

| C7701R-H | t 0.4 | C7701R-H | t 0.64 | HSW-03 | PSW-P1 HSW-EB1 | Weldable Setting 24V, 30ms Only C7701R-H t0.4 can be welded |

| Cu/Sn | t 0.5 | SUS | t 0.2 | HSW-01 | PSW-P1 HSW-EB1 | Weldable Setting 24V, 10ms |

| SUS | t 0.75 | SUS | mesh 100 | HSW-03 | PSW-R2 HSW-EB1 | Weldable Setting 24.8V, 0.1ms The electrodes are HSW-EB1 on the bottom, mesh on the SUS plate, and HSW-R2 from the top. |

| Su | t 0.02 | Cu | t 0.02 * 10 | HSW-03 | PSW-P1 HSW-EB1 | Weldable Setting 13.8V, 0.8ms / 2.0ms Weld strength can be adjusted by setting |

| Ni | t 0.08 | Ni | t 0.08 | HSW-03 | PSW-H3 | Weldable Setting 25V, 0.6ms |

| Ni | t 0.15 | Ni | t 0.15 | HSW-03 | PSW-H3 | Weldable Setting 25V, 1.6ms |

| Al Li-Po | t 0.1 battery | Ni | t 0.08 | HSW-03 | PSW-H3 | Weldable Setting 25V, 0.21ms It is better to use HSW-EB1 on the aluminum side and PSW-P2 on the nickel side. |

| Ni Li-ion | t 0.3 battery | Ni | t 0.25 | HSW-03 | PSW-H3 | Weldable Setting 25V, 30ms |

| Al | t 0.2 | Ni | t 0.08 | HSW-03 | PSW-H3 | Weldable Setting 25V, 10ms |

|

| Fe SS400 | t 20.0 | Cu | φ 0.15 | HSW-03 | PSW-H3 | Weldable Setting 25V, 30ms |

| Fe | t 20.0 | Fe | t 0.3 | HSW-02 | HSW-F1N HSW-CL1 | Weldable Setting 24V, 100μs ~ 3ms Connect the clip electrode to the mold and PSW-P2 to the shim tape Welding pen attached as standard is also available |

| SUS | t 0.3 | SUS mesh | φ 0.025 | HSW-03 | HSW-P1N HSW-EB1 | Weldable Setting 7 to 24V Adjust the tip area of the electrode to about 1 mm Weld strength is adjustable |

|

| Fe | t 20.0 | Al | t 0.2 | HSW-03 | HSW-P1N HSW-EB1 | Weldable Setting: 0.1 mm thick, 25 V, 12 mS |

| SUS304 | t 3.0 | SUS | t 0.3 | HSW-03 | PSW-P1 HSW-EB1 | Weldable Setting: 24V, 30mS |

| parts | ? | Cu/Sn | ? | HSW-02 | PSW-P1 HSW-FB2 | Weldable Settings: 14V ~ 16V, 500μS ~ 1.5mS When the voltage is increased, the board pattern melts. If the electrode pressing pressure is insufficient, a hole will be created. |

|

| R tc | φ 0.2 | R tc | φ 0.2 | HSW-02 | PSW-TC1 | Weldable Setting: 10.8V ~, 100μS |

|

| SUS304 | φ 1.5 | SUS304 | φ 1.5 | HSW-02 | HSW-W2 | Weldable Setting: 24V, 30mS It is possible to reduce the pulse width and the spot mark. |

| Fe | t 20.0 | SUS304 | t 0.62 | HSW-03 | HSW-P1N HSW-EB1 | Weldable but insufficient strength |

| Ni/Cr/Fe/Mn | φ 1.0 | Cu/Ni | φ 1.0 | HSW-03 | PSW-TC1 | Weldable Setting: 9V, 80μS |

| Al | t 0.01 | Al | t 0.02 | HSW-03 | PSW-R2 HSW-EB1 | Seam weldable Setting: 9V, 130μS |

| parts | ? | Cu | ? | HSW-02 | HSW-P1N HSW-EB1 | Weldable Setting: 16V, 300μS ~ 1mS |

| Fe | t 20.0 | Pt | φ 0.08 | HSW-03 | PSW-P1 HSE-FB2 | Weldable Setting: 24V, 30mS |

| Zn | t 0.1 | Zn | t 0.3 | HSW-03 | NG | Not weldable Setting: 25V, 30mS |

| SUS316 | t 0.8 | SUS316 | t 0.8 | HSW-03 | HSW-P1N HSW-EB1 | Weldable Setting: 25V, 30mS |

| SUS | φ 1.0 | SUS | φ 1.0 | HSW-03 | HSW-W2 | Weldable Setting: 14V, 500μS Strength can be adjusted by setting |

| Cu | φ 0.26 | Cu/Ni | φ 0.13 | HSW-01 | HSW-W2 | Weldable Setting: 5.5-7.7V |

| SUS | t 0.5 | SUS | t 0.7 | HSW-02 | HSW-P1N HSW-EB1 | Weldable Setting: 24V HSW-03 machine is recommended when welding strength is required |

| Cu | φ 0.4*7 | Cu/Zn | t 0.4 | HSW-02 | NG | Not weldable Setting: 24V, 60μ-10mS |

|

| Cu/Cr | ? | Cu | ? | HSW-02 | PSW-TC1 | Weldable Setting: 8 to 16V, 60μ to 1mS Temporary welding at 60-100 μs to avoid fusing Then weld and fix in 200-1ms |

|

| SUS | t 0.03 | Cu-Ag | ? | HSW-03 | HSW-P1N HSW-EB1 | Weldable Settings: 16-24V, 60μ-180μS Because the SUS foil is thin, it partially melts |

|

| Fe/Ni:Cu | ? | Cu | ? | HSW-02 | PSW-TC1 HSW-EB1 | Weldable Setting: 18 to 20V, about 1000μS Adjustable welding strength |

|

| Cu:Sn | φ 0.5 | Ag | t 0.05 | HSW-02 | PSW-P1 HSW-EB1 | Weldable Setting: 24V, about 2mS Adjustable welding strength |

|

| Pt | ? | Pt | ? | HSW-02 | PSW-TC1 | Weldable Setting: 24V, 2mS Can be welded up to 1.5 mm width |

|

| Ti | t 0.3 | Pt | φ 0.08 | HSW-03 | PSW-P1 HSW-FB2 | Weldable Over 20 kg in tension strength test |

| Al | t 0.2 | Al | t 0.05 | HSW-03 | PSW-P1 HSW-FB2 | Weldable Setting: 25V, 30ms Seam welding is not possible with the HSW-03 machine |

| SUS | t 2.6 | SUS | t 0.8 | HSW-03 | PSW-P1 HSW-FB2 | Weldable Setting: 25V, 30ms |

| SUS444 | t 3.0 | Fe/Ni/Cr | t 0.05 | HSW-01 | PSW-P1 HSW-FB2 | Weldable |

| SUS | φ 0.23 mesh | SUS | φ 0.23 mesh | HSW-03 | PSW-R2 HSW-FB2 | Weldable φ0.23x45mesh ・ ・ ・ 16.3V, 0.25mS, welding interval 3 times / sec φ0.14x50mesh ・ ・ ・ 16.3V, 0.14mS, welding interval 5 times / sec |

| Cu/? | t 0.2 | Al | t 0.2 | HSW-03 | HSW-W2 | Weldable Setting: 25V, 30mS Insufficient welding strength |

| SUS304 | t 2.0 | SUS304 | φ 2.0 | HSW-03 | custom HSW-FB2 | Weldable Setting: 25V, 3-30mS It is good to have an electrode to hold the SUS wire |

| SUS301 | t 0.1 | SUS | φ 0.5 | HSW-03 | PSW-TC1 custom | Weldable Setting: 10V, 0.6mS Wrap (+) electrode around φ8.0 pipe and weld |

| Al Li-po | t 0.1 battery | Al-Ni | t 0.15 | HSW-03 | PSW-P1 HSW-EB1 | Weldable Setting: 10V, 0.7mS Uses a clad material made by laminating aluminum and nickel to 0.15t |

| K tc | φ 0.025 | K tc | φ 0.025 | HSW-03 | PSW-TC1 | Weldable Settings: 4.5V, 0.02mS |

| Al/Li-ion | battery | Al:Ni | t 0.15 | HSW-03 | PSW-P1 HSW-FB2 | Weldable Settings: 17V, 17mS Place the aluminum side of the nickel / aluminum clad material on the battery, Weld with a welding stick from the nickel side of the clad material |

| Al | t 1.0 | K tc | φ 0.32 | HSW-03 | PSW-P1 HSW-EB1 | Weldable Setting: 14V, 2mS Welding may be done several times in 1.5mS seam mode |

| SUS304 | t 0.1 | Ni | t 0.03 | HSW-03 | PSW-P1 PSW-H3 | Weldable Setting: 11V, 0.8mS Welded with Kapton tape in an environment insulated from the copper plate below |

| CR2032 | battery | CuSn | t 0.15 | HSW-03 | PSW-H3 | Weldable Setting: 17.9V, 30mS Copper tin plating 0.25t cannot be welded |

| Al/ Li-ion | battery | Ni | t 0.6 | HSW-03 | HSW-EB1 PSW-P2 | Not weldable Setting: 25V, 30mS |

|

| Fe? | t 0.1 | Fe? | t 0.1 | HSW-03 | PSW-TFT | Weldable Setting: 25V, 30mS Insufficient welding strength as the wire diameter increases |

| SUS | t 0.5 | SUS | φ 0.2 mesh | HSW-03 | PSW-R2 HSW-EB1 | Weldable Setting: 19.8V, 0.93mS Seam welding mode |

| SUS | t 1.0 | Ta | φ 0.3 | HSW-03 | PSW-P1 HSW-EB1 | Weldable φ0.2: 7.3V, 0.41mS φ0.3: 7.3V, 0.6mS |

| SUS | mesh | SUS | φ 2.9 | HSW-03 | PSW-FB2 HSW-EB1 | Weldable Setting: 25V, 20ms |

| Al | t 0.02 | Cu | t 0.02 | HSW-03 | PSW-P1 HSW-FB2 | Weldable Setting: 25V, 16.7ms |

| Cu:Ni | t 1.0 | K tc | φ 0.3 | HSW-03 | HSW-FB2 PSW-P2 | Not weldable Setting: 25V, 30ms |

| Cu | AWG 10 | CuTO92 | φ 0.3 | HSW-03 | HSW-EB1 PSW-P2 | Not weldable |

| SUS | t 0.05 | SUS | t 0.05 | HSW-03 | PSW-P2 HSW-FB2 | Weldable Setting: 12.3V, 0.3ms |

| Fe | ? | Fe | ? | HSW-03 | PSW-P2 HSW-EB1 | Not weldable |

| Al | ? | K tc | φ 0.3 | HSW-03 | PSW-P1 HSW-FB2 | Weldable Setting: 18V, 0.21ms |

| SUS | mesh | SUS | mesh | HSW-03 | PSW-P1 HSW-FB2 | Weldable Setting: 12V, 0.5ms |

| K tc | φ 0.025 | K tc | φ 0.025 | HSW-03 | PSW-TC1 | Weldable Setting: 5V, 0.03ms |

| E tc | φ 0.025 | Cu | φ 0.1 | HSW-03 | PSW-P1 HSW-EB1 | Weldable Setting: 4.6V, 0.08ms |

| SUS | φ 0.5 | SUS | φ 0.5 | HSW-03 | custom PSW-FTF | Weldable Settings: 25V, 0.24mS (φ0.5) / 25V, 0.5mS (φ0.85) / 25V, 0.9mS (φ0.94) |

| SUS | t 0.3 | SUS | t 0.3 | HSW-02 | PSW-P1 HSW-EB1 | Weldable Setting: 25V, 22mS |

| SUS | φ 15.0 | SUS | φ 0.6 | HSW-03 | PSW-P1 HSW-EB1 | Weldable Settings: φ0.6 12V, 3.0 ~ 6.0mS / φ0.35 12V, 0.3 ~ 1.0mS / φ0.1 9.7V, 0.1mS |

| SUS | t 2.0 | SUS | mesh | HSW-03 | PSW-R2 HSW-FB2 | Weldable Setting: 12V, 0.21ms |

| Ni/Fe/Cr | t 0.1 | Inconel | t 0.1 | HSW-03 | PSW-R2 HSW-FB2 | Weldable Settings: Seam mode ① 12V 1.6mS ② 18V 1.6mS ③ 20V 1.0mS |

|

| R tc | φ 0.5 | R tc | φ 0.5 | HSW-03 | custom HSE-EB1 | Weldable Setting: 12V, 0.26ms |

| R tc | φ 0.3 | Cu | ? | HSW-03 | PSW-TC1 HSW-EB1 | Weldable Setting: 18V, 0.34ms |

| SUS | t 0.15 | SUS | t 0.15 | HSW-03 | PSW-P1 HSW-FB2 | Weldable Setting: 25V, 1.2ms |

| K tc | φ 0.18 | K tc | φ 0.5 | HSW-03 | PSW-TC1 HSW-FB2 | Weldable Setting: 6.3V, 0.6ms Weld strength adjustable |

| Cu/Sn | ? | Cu/Sn:Ni | ? | HSW-03 | PSW-P1 HSW-FB2 | Weldable Setting: 21V, 0.3 ~ 0.7mS |

|

| Ni | filter | Ni | ? | HSW-02 | PSW-P1 HSW-FB2 | Weldable | |

| Fe | t 0.1 | Fe | t 0.05 | HSW-03 | PSW-R2 HSW-FB2 | Weldable Setting: 15 to 20V, 0.2 to 0.3mS |

| SUS | φ 0.5 | SUS | φ 0.8 | HSW-03 | PSW-TFT custom | Weldable Settings: 5V, 0.24mS (φ0.5) / 25V, 0.5mS (φ0.85) / 25V, 0.9mS (φ0.94) |

| Ni/Ti | φ 0.3 | Ni/Ti | φ 0.3 | HSW-03 | PSW-P1 HSW-FB2 | Weldable Setting: 14.6V, 0.12ms |

| SUS | t 1.0 | SUS | t 0.1 | HSW-03 | PSW-P1 HSW-FB2 | Weldable Setting: 20V, 3-5ms |

|

| SR416S | battery | Ni | ? | HSW-03 | HSW-P1S | Weldable |

| Fe | t 20.0 | Fe | t 0.1 | HSW-03 | PSW-P1 HSW-EB1 | Weldable Settings: 25V, 30mS / 16V, 6mS |

| Fe SKD-61 | t 0.15 | Ni | t 0.2 | HSW-02 | PSW-TC1 HSW-EB1 | Weldable Setting: 9.3V |

| Pt | t 0.2 | Cu | φ 0.8 | HSW-03 | PSW-P1 HSW-FB2 | Weldable Setting: 24V, 30mS |

| Li-ion | battery | Al-Ni BatTab | t 0.1 | HSW-03 | PSW-P1 HSW-FB2 | Weldable Setting: 17V, 12mS The welding stick is (+) and the flat plate electrode side is (-). |

| Cu Alloy | t 0.07 | Cu | t 3.0 | HSW-04 | PSW-P2 HSW-FB2 | Weldable Setting: 25V, 25ms Welding is not possible with the HSW-03 machine |

| FeCr | φ 2.6 | K tc | φ 0.1 | HSW-03 | HSW-TC1 | Weldable Settings: 10.6V, 0.37ms |

| Al | t 1.0 | K tc | φ 0.1 | HSW-03 | PSW-02 HSW-FB2 | Weldable Setting: 15.2V, 0.33ms Difficult to weld directly Weld the Al-Ni clad material and weld the thermocouple on it. |

| NCR18650BF | battery | Ni | t 0.12 | HSW-03 | PSW-H3 | Weldable Setting: 23V, 6ms |

| SUS | t 10.0 | SUS | t 0.5 | HSW-03 | HSW-FB2 PSW-R2 | Weldable Setting: 20V, 1.5ms |

| SUS spring | φ 1.6 | SUS spring | φ 2.5 | HSW-03 | custom | Weldable Setting: 25V, 2.6ms Insufficient welding strength |

| R tc | φ 0.3 | Cu Al | φ 4.0 φ 6.5 | HSW-03 | HSW-FB2 PSW-P1 | Weldable Setting: 20V, 1.5ms |

| Pt | φ 0.15 | Cu | φ 0.12 | HSW-03 | PSW-TC1 | Weldable Setting: 10.8V, 0.18ms Hold with oil tweezers, sandwich between PSW-TC1 electrodes and weld |

| NiCr | φ 2.0 | SUS | φ 1.0 | HSW-03 | HSW-EB1 PSW-P1 | Weldable Setting: 15V, 1.5ms Welding is possible even with HSW-02A machine |

| SUS304 | φ 0.1 | SUS304 | φ 0.1 | HSW-03 | PSW-TC1 | Weldable Setting: 7V, 0.15ms |

| K tc | φ 0.5 | K tc | φ 0.5 | HSW-03 | PSW-TC1 | Weldable Setting: 14V, 1.0ms |

| SUS | mesh | SUS | mesh | HSW-03 | HSW-FB2 PSW-R2 | Weldable Setting: 15V, 1.0ms |

| K tc | φ 0.1 | Cu | t 0.1 | HSW-03 | HSW-Eb1 PSW-P1 | Weldable Setting: 20V, 1.5ms Welding of Cu0.3 and Almel wire is difficult (+) Rod-shaped electrode-K thermocouple-Cu plate-Welding stick (-) |

| K tc R tc | φ 0.1 | Al | t 3.0 | HSW-03 | PSW-P1 HSW-FB2 | Weldable Setting: 18V, 8.0ms Direct welding of K thermocouple to Al plate is not possible Welded tc on top of welded Al-Ni clad material |

| Al | ? | Ti | t 0.12 | HSW-03 | HSW-FB2 PSW-P1 | Weldable Setting: 25V, 16.5ms |

| Cu | t 0.3 | Cu | φ 0.1 | HSW-03 | PSW-H3 | Weldable Setting: 8.7V, 0.58ms |

| Parts | K tc | φ 0.8 | HSW-03 | HSW-FB2 PSW-P1 | Weldable Setting: 20V, 1.5ms HSW-04 is recommended due to lack of strength |

|

| T tc | φ 0.2 | contact | ? | HSW-03 | PSW-TC1 | Weldable Setting: 12V, 1.0ms |

| Al | t 0.2 | Ni-Cu | t 0.2 | HSW-03 | HSW-FB2 PSW-P1 | Not weldable | |

| Zn-Fe | φ 2.5 | Zn-Fe | φ 2.5 | HSW-03 | HSW-EB1 PSW-P1 | Weldable Setting: 12V, 1.5ms Welding is possible even at 25V, 30mS However, due to the effect of zinc plating, the copper of the electrode is damaged. Welding can also be done by sandwiching a thin brass plate |

| Al | t 2.0 | K tc | φ 0.65 | HSW-03 | HSW-W2 | Weldable Setting: 15V, 8ms |

| NiCr | φ 2.0 | SUS | φ 1.0 | HSW-03 | PSW-P1 HSW-EB1 | Weldable |

| SUS | mesh | SUS | mesh | HSW-03 | PSW-R2 HSW-FB2 | Weldable Setting: 15V, 1ms |

| SUS | t 10.0 | SUS | t 0.5 | HSW-02A | PSW-P1 HSW-FB2 | Weldable Setting: 24V |

| K tc | contact | K tc | contact | HSW-03 | PSW-TC1 | Weldable Setting: 8.6V, 1.0ms |

| SUS304 | t 0.8 | SUS | t 0.8 | HSW-03 HSW-04 | PSW-P1 HSW-CL1 | Weldable Setting: 25V, 30ms |

| K tc R tc | contact | Al | t 3.0 | HSW-03 | PSW-P1 HSW-FB2 | Weldable Setting: 18V, 8ms K thermocouple cannot be welded to Al plate, thermocouple is welded on Al-Ni clad material |

| Al | ? | Ti | ? | HSW-03 | PSW-P1 HSW-FB2 | Weldable Setting: 25V, 16ms If you want to increase the strength, you need HSW-04 machine |

| Cu | t 0.3 | Cu | φ 0.3 Spherical | HSW-03 | PSW-P1 HSW-FB2 | Weldable Setting: 25V, 1ms |

| Al | t 0.2 | Ni:Fe | t 0.2 | HSW-03 | PSW-P1 HSW-EB1 | Insufficient welding strength Setting: 25V, 30ms |

|

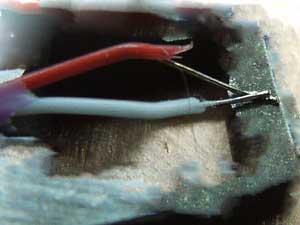

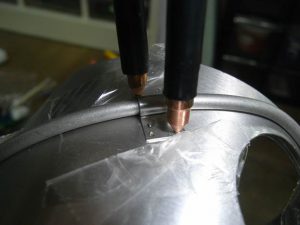

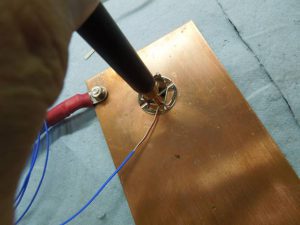

| Zn:Fe | φ 2.5 | Zn:Fe | φ 2.5 | HSW-03 | PSW-P1 HSW-EB1 | Weldable Setting: 25V, 30ms Copper is damaged during welding. This gives an energizing route to the iron wire side with a clip electrode as shown in the photo, You can avoid it to some extent by doing it |

| T tc | φ 0.065 | T tc | φ 0.065 | HSW-03 | PSW-T1 HSW-FB2 | Weldable Setting: 6.1V, 0.6 / 0.3 / 0.17ms three times |

| SUS | parts | SUS | t 0.5 | HSW-02A | PSW-P1 HSW-CL1 | Weldable Setting: 15V, 1ms |

| Ag | φ 0.3 | Ag | φ 0.3 | HSW-02A | PSW-TC1 | Weldable HSW-03 machine is recommended if you want to increase the welding strength |

| Al Current collector | 15μm | Al tab | 100μm | HSW-03 | PSW-P1 HSW-FB2 | Weldable Setting: 15V, 1ms |

| Cu Current collector | 15μm | Cu tab | 100μm | HSW-03 | PSW-P1 HSW-FB2 | Weldable Setting: 15V, 1ms |

| Ti | parts | K tc | φ 0.2 | HSW-03 | PSW-P1 HSW-FB2 | Weldable Setting: 15V, 0.2-0.6ms Seam welding mode |

|

| SUS | mesh parts | SUS | mesh | HSW-03 | PSW-R5 HSW-FB2 | Weldable Setting: 20V, 0.4ms Seam welding mode |

| T tc | Spherical | Mo | parts | HSW-03 | PSW-P1 HSW-FB2 | Weldable Setting: 20V, 0.5ms In normal welding, it was blown by sparks or flash welded. Welding is good while increasing the energizing time from 0.02 mS to 0.8 mS in seam welding mode. |

| SUS304H | parts | SUS | pipe φ 3.0 t 0.5 | HSW-03 | PSW-P1 HSW-FB2 | Weldable Setting: 25V, 2ms |

|

| Al | Capacitor parts | Al | Capacitor parts | HSW-03 | PSW-R5 HSW-FB2 | Weldable Setting: 15V, 1ms HSW-R2 can also be used, but since the foil is thin, R5 with good operability is used. |

| K tc | contact | Solder | PCB | HSW-03 | PSW-TC1 HSW-W2 | Weldable Setting: 20V, 0.3ms Since the copper foil thickness of the printed circuit board is thin and it melts, It is better to weld over solder plating |